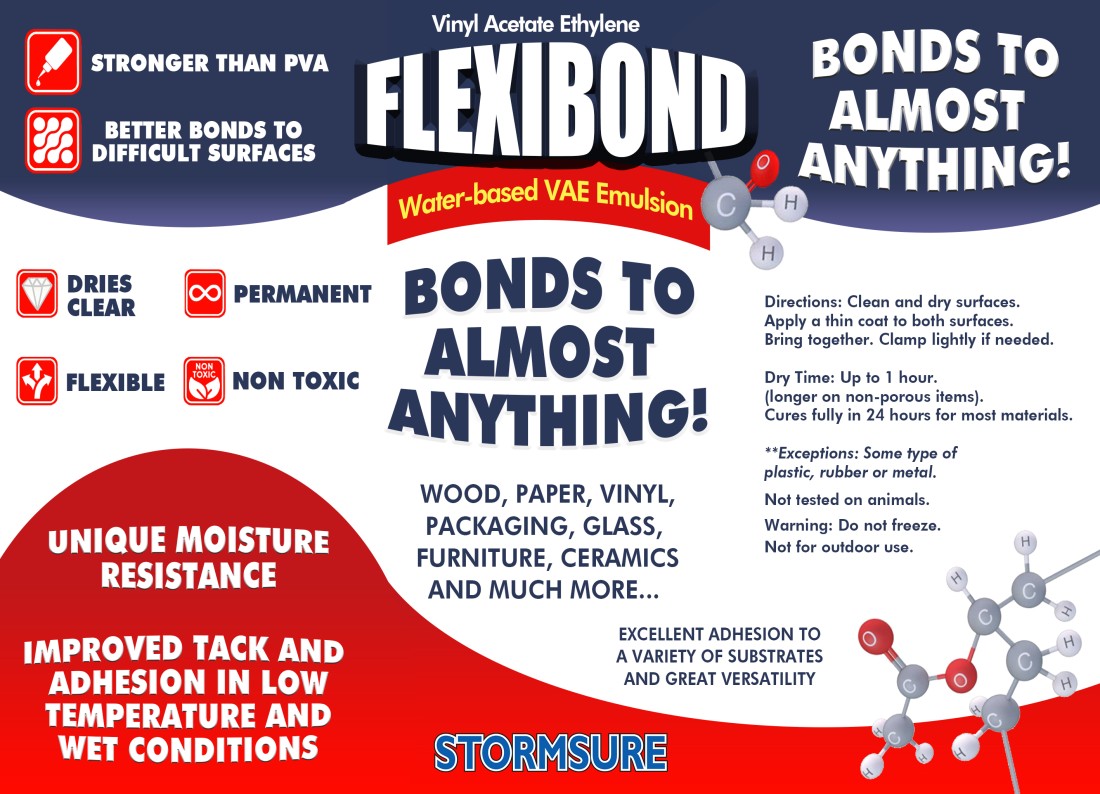

FLEXIBOND Vinyl Acetate Ethylene (VAE) is a type of water-based adhesive that is known for its high bonding strength and resistance to water, heat, and chemicals. Flexibond is composed of a polymer blend of vinyl acetate and ethylene, and it is often used in applications where a strong and durable bond is required, such as in woodworking, furniture manufacturing, and paperboard lamination.

Compared to other adhesives, Flexibond is considered to be a more environmentally friendly option because it contains fewer volatile organic compounds (VOCs) and has a lower carbon footprint. It is also non-toxic and odorless, making it a safer choice for use in indoor environments.

FLEXIBOND Vinyl Acetate Ethylene (VAE) Copolymers are formed by the copolymerisation of vinyl acetate and ethylene. Flexibond offers unique moisture resistance, flexibility, improved tack and adhesion in low temperature and wet conditions. It adheres well to non porous surfaces like vinyl, aluminium, glass etc.

Copolymers of FLEXIBOND Vinyl Acetate Ethylene (VAE or EVA) are ideal polymeric binders for paper & packaging applications. Their special chemistry makes it easy to serve the market drivers in the adhesives industry.

Vinyl acetate is a hard, rigid, hydrophilic polymer. Ethylene is very soft, non-polar and hydrophobic. Together, they make perfect partners for copolymerisation. VAE (EVA) copolymers are notable for their excellent adhesion to a variety of substrates, great versatility and very low migration potential.

These benefits are provided by the ethylene, which works as an internal plasticiser and used to set the softness and permanent flexibility, without the need for additional plasticisers.

VAE adhesives and PVA adhesives are two different types of adhesives used in the construction and woodworking industries. While both adhesives are commonly used for bonding wood and other porous substrates, they differ in their chemical composition and properties.

VAE versus PVA adhesives

PVA Adhesives

PVA adhesive (Polyvinyl Acetate) is another type of water-based adhesive that is known for its ease of use, safe to handle and low cost. PVA adhesive is composed of a synthetic polymer made from vinyl acetate monomer, and it is often used in applications where a low-to-medium strength bond is required, such as in bookbinding, paper packaging, and labeling. As a water-based adhesive, PVA is easy to clean. PVA glue doesn’t emit strong fumes, reducing the need for additional ventilation. PVA adhesive glue is a cost-effective commercial adhesive.

PVAs can be found in an incredible number of everyday products including: –

Corrugated cases

Books

Kitchen worktops

Toilet rolls

Paper bags

Beds & Sofas

Printed cartons

Postal tubes

Doors

VAE Adhesives

VAE adhesives are widely used for paper packaging, bookbinding and furniture manufacture. Whilst they are identical in appearance to PVAs – differences in their chemical characteristics make them much more suitable for bonding difficult materials such as packaging films, printed and varnished boards and furniture films. They are higher in cost than PVAs, easy to use and safe to handle.

VAEs can be found in an incredible number of everyday products including: –

Printed & varnished cartons

Books

Envelopes

Film fronted bags

Furniture and decoration

Window cartons

Presentation tubes

Files & folders

Paint and coating

Construction

VAE Adhesives offer the following advantages versus PVA adhesives

VAE adhesives provide better bonds to difficult surfaces such as varnished and laminated papers/boards.

VAE’s provide a higher initial tack which is important in all high-speed applications, particularly where there is limited compression time

Have a more flexible final glue film providing improved performance at low temperature. This makes them particularly suitable for manufacturing paper/cardboard deep freeze packaging for the food industry.

While both VAE and PVA adhesives are water-based and commonly used in woodworking and paper industries, they differ in their chemical composition, strength, and cost.