Watersports

Gear for the repair and mainaintance of wetsuits, drysuits and watersports equipment

-

TUFF Tape Waterproof Durable Patches: 5-Pack of 75mm Diameter Self-Adhesive for Quick Fixes£5.95

Stormsure ’TUFF Tape’ is a very strong, clear, self-adhesive, waterproof tape that is sold as individual pre-cut patches and strips of various shapes and sizes. TUFF Tape is made of a thin, but very tough, polyurethane film with a pressure sensitive adhesive and backing paper on the rear side. It has characteristics unlike many other tapes. It is waterproof and air tight. It is highly resistant to abrasion and very difficult to tear or puncture. It stretches and is elastic and it can withstand both heat and extreme cold without losing all its useful characteristics. TUFF Tape is very strong and can bind together items just by stretching the tape around the item and using the elasticity to pull the pieces tightly into place. When TUFF tape is applied to clothing it will go through regular washing machine cycles unaffected.

USES: Use TUFF Tape to quickly repair rips in waterproof clothing, ripped netting and fabrics, inflatable mattresses, canoes and RIBs, tents and awnings, sails and kites, waders, cracked buckets and other plastic containers, PVC curtain sides on trucks and warehouses.

DIRECTIONS: Ensure that the surface is clean and dry before using. Cut a suitable sized piece of TUFF Tape for your repair using good quality scissors or a sharp scalpel blade. Peel off the backing paper. Carefully position and then apply the TUFF Tape directly on top of the damage. Start at one edge and press the tape down gradually to avoid the entrapment of air bubbles. Once the TUFF Tape is in place rub it firmly with a smooth and hard object (such as the back of a spoon) to ensure the maximum adhesion to the substrate.

-

TUFF Tape Waterproof Patches: 2-Pack of 75mm Diameter Self-Adhesive for Quick Fixes£3.95

Stormsure ’TUFF Tape’ is a very strong, clear, self-adhesive, waterproof tape that is sold as individual pre-cut patches and strips of various shapes and sizes. TUFF Tape is made of a thin, but very tough, polyurethane film with a pressure sensitive adhesive and backing paper on the rear side. It has characteristics unlike many other tapes. It is waterproof and air tight. It is highly resistant to abrasion and very difficult to tear or puncture. It stretches and is elastic and it can withstand both heat and extreme cold without losing all its useful characteristics. TUFF Tape is very strong and can bind together items just by stretching the tape around the item and using the elasticity to pull the pieces tightly into place. When TUFF tape is applied to clothing it will go through regular washing machine cycles unaffected.

USES: Use TUFF Tape to quickly repair rips in waterproof clothing, ripped netting and fabrics, inflatable mattresses, canoes and RIBs, tents and awnings, sails and kites, waders, cracked buckets and other plastic containers, PVC curtain sides on trucks and warehouses.

DIRECTIONS: Ensure that the surface is clean and dry before using. Cut a suitable sized piece of TUFF Tape for your repair using good quality scissors or a sharp scalpel blade. Peel off the backing paper. Carefully position and then apply the TUFF Tape directly on top of the damage. Start at one edge and press the tape down gradually to avoid the entrapment of air bubbles. Once the TUFF Tape is in place rub it firmly with a smooth and hard object (such as the back of a spoon) to ensure the maximum adhesion to the substrate.

-

TUFF Tape Self Adhesive Waterproof Repair Tape 0.5m x 75mm£5.95

Stormsure ’TUFF Tape’ is a very strong, clear, self-adhesive, waterproof tape that is sold as individual pre-cut patches and strips of various shapes and sizes. TUFF Tape is made of a thin, but very tough, polyurethane film with a pressure sensitive adhesive and backing paper on the rear side. It has characteristics unlike many other tapes. It is waterproof and air tight. It is highly resistant to abrasion and very difficult to tear or puncture. It stretches and is elastic and it can withstand both heat and extreme cold without losing all its useful characteristics. TUFF Tape is very strong and can bind together items just by stretching the tape around the item and using the elasticity to pull the pieces tightly into place. When TUFF tape is applied to clothing it will go through regular washing machine cycles unaffected.

USES: Use TUFF Tape to quickly repair rips in waterproof clothing, ripped netting and fabrics, inflatable mattresses, canoes and RIBs, tents and awnings, sails and kites, waders, cracked buckets and other plastic containers, PVC curtain sides on trucks and warehouses.

DIRECTIONS: Ensure that the surface is clean and dry before using. Cut a suitable sized piece of TUFF Tape for your repair using good quality scissors or a sharp scalpel blade. Peel off the backing paper. Carefully position and then apply the TUFF Tape directly on top of the damage. Start at one edge and press the tape down gradually to avoid the entrapment of air bubbles. Once the TUFF Tape is in place rub it firmly with a smooth and hard object (such as the back of a spoon) to ensure the maximum adhesion to the substrate.

EAN: 5060219660667

-

TUFF Tape Durable Repair Strip: 1m Waterproof Adhesive for Outdoor Gear Fixes£7.96

Stormsure ’TUFF Tape’ is a very strong, clear, self-adhesive, waterproof tape that is sold as individual pre-cut patches and strips of various shapes and sizes. TUFF Tape is made of a thin, but very tough, polyurethane film with a pressure sensitive adhesive and backing paper on the rear side. It has characteristics unlike many other tapes. It is waterproof and air tight. It is highly resistant to abrasion and very difficult to tear or puncture. It stretches and is elastic and it can withstand both heat and extreme cold without losing all its useful characteristics. TUFF Tape is very strong and can bind together items just by stretching the tape around the item and using the elasticity to pull the pieces tightly into place. When TUFF tape is applied to clothing it will go through regular washing machine cycles unaffected.

USES: Use TUFF Tape to quickly repair rips in waterproof clothing, ripped netting and fabrics, inflatable mattresses, canoes and RIBs, tents and awnings, sails and kites, waders, cracked buckets and other plastic containers, PVC curtain sides on trucks and warehouses.

DIRECTIONS: Ensure that the surface is clean and dry before using. Cut a suitable sized piece of TUFF Tape for your repair using good quality scissors or a sharp scalpel blade. Peel off the backing paper. Carefully position and then apply the TUFF Tape directly on top of the damage. Start at one edge and press the tape down gradually to avoid the entrapment of air bubbles. Once the TUFF Tape is in place rub it firmly with a smooth and hard object (such as the back of a spoon) to ensure the maximum adhesion to the substrate.

-

Premium Neoprene Queen Wetsuit Repair Kit£7.99

After much feedback from our customers we have now launched our NEW IMPROVED FORMULA for Neoprene Queen. We are delighted that this much improved adhesive formula will now work with all neoprene materials and now also with latex, pvc and many other materials too! It is now the complete adhesive solution for anything water sports!

Special neoprene glue to repair your diving and swimming suit.

Neoprene Queen is an essential part of the maintenance kit for your wetsuit.

Its fast drying and resistance allows you to repair holes and tears in your neoprene wetsuit (surf, kitesurf, windsurf, etc) in just 20 minutes.

It is perfect for last minute repairs. Imagine, you are on the beach or next to a river and you have just damaged your wetsuit but still want to get back in the water. With Neoprene Queen, no need for patches, just apply the glue on the 2 edges of the tear, wait 2 min, then press the 2 edges together.Neoprene Queen will quickly become an essential element for all casual water sports enthusiasts, Triathletes, Surfers, Swimmers, Divers, Kite Boarders, Body Boarders, Fishermen and many more!

Neoprene Queen Adhesive is a fast-curing, thick, black glue. Its premium quality and properties make it perfect for repairing wetsuit and drysuit damage that regularly occurs over time with regular use. This special adhesive will enable you to make easy and durable repairs to rips, tears, leaks and split seams on wetsuit and drysuit material.

To use, apply to both edges of a rip and bond firmly together for 20 seconds. Within 20 minutes, it should be touch dry and you will be ready to go back in the water!

After much feedback from our customers we have now launched our NEW IMPROVED FORMULA for Neoprene Queen. We are delighted that this much improved adhesive formula will now work with all neoprene materials and now also with latex, pvc and many other materials too! It is now the complete adhesive solution for anything water sports!

Neoprene Queen Adhesive is a fast-curing, thick, black glue. Its premium quality and properties make it perfect for repairing wetsuit and drysuit damage that regularly occurs over time with regular use. This nifty adhesive will enable you to make easy and durable repairs to rips, roles, leaks and split seams on wetsuit and drysuit material.

To use, apply to both edges of a rip and bond firmly together for 20 seconds. Within 5 minutes, it should be touch dry and you will be ready to go back in the water!

An essential tool for divers, anglers, surfers, body boarders, kite surfers and sailors.

Perfect for casual water sports enthusiasts as well as professional triathletes who want to stand out.

-

Stormoprene Part B Activator for Hypalon 2-Part Contact Adhesive (A3707) 200ml£17.94

Part B Activator to be used with Stormoprene Hypalon Part A Contact Adhesive (A3707).

-

Stormsure Leak Detector 30ml£6.98

Use this excellent product to find pin hole leaks in breatheable and waterproof fabric. Just spray it on the suspect area and see the leaks on the other side.

The breathable fabric is hydrophobic, so when you try to find a pin hole in you waders under the kitchen tap, the water is repelled from the small holes and forms spheres of water which role off the fabric. It is only when the leak is under a meter or more of water pressure that the water will be forced through the pin holes and onto your feet ( i.e. when you are waste deep in water in your waders!)

Once the holes are identified you can repair the area with Stormsure Flexible Repair Adhesive or a TUFF patch.

Comes in a 30ml bottle with finger pump sprayer.

-

Stormoprene Hypalon 2-Part Contact Adhesive 5 Litres (A3707)£155.83

Stormoprene Hypalon Adhesive is a specially formulated 2-part poly-chloroprene based adhesive system for high-performance bonding of Hypalon and other natural and synthetic rubber surfaces that require high strength bonds for use in demanding applications.

Formulated for use in the manufacture and repair of RIBs, inflatable boats, liferafts, diving suits, wet suits and other marine and industrial applications that specify resistance to salt water, oil, fuels etc.

- Easy to mix two part system supplied with Activator/curing agent.

- Easy to apply by brush or roller.

- Contact bonds in 10-15 minutes, full cure 48 hours.

- Shelf life: 3-12 months unopened tin, mixed adhesive has pot life of 3-4 hours

You can use just the glue (as a single component glue) on many fabrics, but the activator must be mixed with the adhesive when used to stick Hypalon fabric.

Securely bonds Hypalon: developed specifically for bonding Hypalon

Hypalon is ideal for creating marine products because it is hardwearing, yet flexible. It is also resistant to chemicals, extreme temperatures and ultraviolet light. However, these properties also make it difficult to bond. Stormoprene (A3703) ensures a strong bond because it has been developed to take into account the unique properties of Hypalon.Withstands extreme environmental conditions: heat, chemical and water-resistant

Many Hypalon products are subject to wear and tear; boats, marine fenders and dracone barges are subject to harsh treatment when in unsettled waters, whilst wet suits are placed in and out of sea water and left to dry in the sun. Most adhesives could not withstand such extreme conditions. Stormoprene (A3703) ensures a safe and secure bond in these conditions because it has a temperature resistance of -30°C - 120°C and is resistant to both sea water and chemicals.Directions:

1. Mix components A (adhesive) & B (curing agent) for approx. five minutes. Ideally, mix in the proportions supplied or by components A & B at a ratio of 100:6 by weight.

2. Apply an even coat of the mixed adhesive to both surfaces with a brush, roller coater or serrated trowel. Allow the adhesive to dry for 5-15 minutes or until it is dry to touch.

Please note: Applying two thin coats of adhesive is preferable to ensure maximum adhesion. Leave the first coat to dry for approximately 20-30 minutes before applying the final coat. Allow the final coat to dry for 5 to 15 minutes.

3. Join the surfaces together using as much pressure as possible. This is to prevent air entrapment. Components may be handled within minutes of being bonded.

-

Stormsure Latex Wrist Seal Repair Kit (Cone Shape)£19.00

This kit contains all the components that you need to replace the Cone shaped wrist seal on a drysuit. Full instructions are on the pack. Make a good quality water tight repair at a fraction of the cost of sending the suit away for repair.

Stormsure Cone Shaped Wrist Seal

High Quality Latex made in the UK

Size: Medium

Top Cone: 38mm diameter

Bottom Cone: 89mm diameter

Height: 130mm

Stormoprene Adhesive

Stormoprene Hypalon Adhesive is a specially formulated 2-part poly-chloroprene based adhesive system for high-performance bonding of Hypalon and other natural and synthetic rubber surfaces that require high strength bonds for use in demanding applications.

Formulated for use in the manufacture and repair of RIBs, inflatable boats, liferafts, diving suits, wet suits and other marine and industrial applications that specify resistance to salt water, oil, fuels etc.

Directions:

1. Cut off the damaged seal, leaving the part of the suit where the factory seal is attached to the fabric. The new seal will be glued over the old factory seal edge.

2. Slide the new seal into the factory edge and put an elastic band or bungee around the suit to keep it in place. Slide some silicone/wax paper under the cut off edge to keep glue from sticking to the seal, or you can put wax on the seal.

3. Clean the edge of the suit and the new seal edge with solvent (the side with the stripes is the inside.) Gently sand paper it to roughen the surface. Do not let the seal stick out too far, as the small end of the seal should not be stretched over it. It might cause the new seal to slide out of position.

4. Slide the seal on over the factory rubber area. You can put elastic bands around to keep the new seal from sliding.

5. Roll back the new seal so that the 2cm edge that was over the old suit is now facing up. Apply a thin layer of Stormoprene Contact Adhesive to each side. Wait 5 minutes and apply a second layer of adhesive to each side. Use a spatula or knife to apply the glue. When the glue is touch dry, roll the new latex seal right into place over the rubber part of the old seal. It bonds instantly. Press firmly over the glue area to ensure full adhesion.

6. Take your time.

-

Stormsure Latex Neck Seal Repair Kit£23.99

This kit contains all the components that you need to replace the neck seal on a drysuit. Full instructions are on the pack. Make a good quality water tight repair at a fraction of the cost of sending the suit away for repair.

Stormsure Neck Seal

High Quality Latex made in the UK

Size: Medium

Top Cone: 89mm diameter

Bottom Cone: 254mm diameter

Stormoprene Adhesive

Stormoprene Hypalon Adhesive is a specially formulated 2-part poly-chloroprene based adhesive system for high-performance bonding of Hypalon and other natural and synthetic rubber surfaces that require high strength bonds for use in demanding applications.

Formulated for use in the manufacture and repair of RIBs, inflatable boats, liferafts, diving suits, wet suits and other marine and industrial applications that specify resistance to salt water, oil, fuels etc.

Directions:

1. Cut off the damaged seal, leaving the part of the suit where the factory seal is attached to the fabric. The new seal will be glued over the old factory seal edge.

2. Slide the new seal into the factory edge and put an elastic band or bungee around the suit to keep it in place. Slide some silicone/wax paper under the cut off edge to keep glue from sticking to the seal, or you can put wax on the seal.

3. Clean the edge of the suit and the new seal edge with solvent (the side with the stripes is the inside.) Gently sand paper it to roughen the surface. Do not let the seal stick out too far, as the small end of the seal should not be stretched over it. It might cause the new seal to slide out of position.

4. Slide the seal on over the factory rubber area. You can put elastic bands around to keep the new seal from sliding.

5. Roll back the new seal so that the 2cm edge that was over the old suit is now facing up. Apply a thin layer of Stormoprene Contact Adhesive to each side. Wait 5 minutes and apply a second layer of adhesive to each side. Use a spatula or knife to apply the glue. When the glue is touch dry, roll the new latex seal right into place over the rubber part of the old seal. It bonds instantly. Press firmly over the glue area to ensure full adhesion.

6. Take your time.

-

Stormoprene Part B Activator for Hypalon 2-Part Contact Adhesive (A3707) 10ml£4.98

Part B Activator to be used with Stormoprene Hypalon Part A Contact Adhesive (A3707).

-

Neoprene Queen Wetsuit Repair Adhesive 5g£1.99 As low as £1.50

Neoprene Queen Adhesive is a fast-curing, thick, black glue. Its premium quality and properties make it perfect for repairing wetsuit and drysuit damage that regularly occurs over time with regular use. This nifty adhesive will enable you to make easy and durable repairs to rips, roles, leaks and split seams on wetsuit and drysuit material.

To use, apply to both edges of a rip and bond firmly together for 20 seconds. Within 5 minutes, it should be touch dry and you will be ready to go back in the water!

An essential tool for divers, anglers, surfers, body boarders, kite surfers and sailors.

Perfect for casual watersports enthusiasts as well as professional triathletes who want to stand out.

-

STORMSURE LATEX 3D SOCKS REPAIR KIT (Pair)£19.99

This kit contains all the components that you need to replace the socks on a drysuit. Full instructions are on the pack. Make a good quality water tight repair at a fraction of the cost of sending the suit away for repair.

Latex socks come in two types 2D and 3D. 2D socks are flat whereas 3D socks have a foot shape moulded in. An important difference is the dimension across the top which determines which type can be fitted to which suit. Measure the ankle of the suit where the new sock is to be fitted. If you measure this flat across and then double it you get the circumference. Ideally the suit should be 1-2cm bigger than the sock which allows the latex to slightly stretch which gives the best finish. If the sock is bigger than the suit you will end up with creases in the latex which will probably leak.

Stormsure 3D Latex Socks

High Quality Latex made in the UK

Size: Large

Top Sock: 133mm diameter

Bottom Sole length: 290mm

Height: 290mm

Stormoprene Adhesive

Stormoprene Hypalon Adhesive is a specially formulated 2-part poly-chloroprene based adhesive system for high-performance bonding of Hypalon and other natural and synthetic rubber surfaces that require high strength bonds for use in demanding applications.

Formulated for use in the manufacture and repair of RIBs, inflatable boats, liferafts, diving suits, wet suits and other marine and industrial applications that specify resistance to salt water, oil, fuels etc.

Directions:

1. Cut off the damaged seal, leaving the part of the suit where the factory seal is attached to the fabric. The new seal will be glued over the old factory seal edge.

2. Slide the new seal into the factory edge and put an elastic band or bungee around the suit to keep it in place. Slide some silicone/wax paper under the cut off edge to keep glue from sticking to the seal, or you can put wax on the seal.

3. Clean the edge of the suit and the new seal edge with solvent (the side with the stripes is the inside.) Gently sand paper it to roughen the surface. Do not let the seal stick out too far, as the small end of the seal should not be stretched over it. It might cause the new seal to slide out of position.

4. Slide the seal on over the factory rubber area. You can put elastic bands around to keep the new seal from sliding.

5. Roll back the new seal so that the 2cm edge that was over the old suit is now facing up. Apply a thin layer of Stormoprene Contact Adhesive to each side. Wait 5 minutes and apply a second layer of adhesive to each side. Use a spatula or knife to apply the glue. When the glue is touch dry, roll the new latex seal right into place over the rubber part of the old seal. It bonds instantly. Press firmly over the glue area to ensure full adhesion.

6. Take your time.

-

Stormoprene Hypalon 2-Part Contact Adhesive 250ml£24.95

Stormoprene Hypalon Adhesive is a specially formulated 2-part poly-chloroprene based adhesive system for high-performance bonding of Hypalon and other natural and synthetic rubber surfaces that require high strength bonds for use in demanding applications.

Formulated for use in the manufacture and repair of RIBs, inflatable boats, liferafts, diving suits, wet suits and other marine and industrial applications that specify resistance to salt water, oil, fuels etc.

- Easy to mix two part system supplied with Activator/curing agent.

- Easy to apply by brush or roller.

- Contact bonds in 10-15 minutes, full cure 48 hours.

- Shelf life: 3-12 months unopened tin, mixed adhesive has pot life of 3-4 hours

You can use just the glue (as a single component glue) on many fabrics, but the activator must be mixed with the adhesive when used to stick Hypalon fabric.

Securely bonds Hypalon: developed specifically for bonding Hypalon

Hypalon is ideal for creating marine products because it is hardwearing, yet flexible. It is also resistant to chemicals, extreme temperatures and ultraviolet light. However, these properties also make it difficult to bond. Stormoprene (A3703) ensures a strong bond because it has been developed to take into account the unique properties of Hypalon.Withstands extreme environmental conditions: heat, chemical and water-resistant

Many Hypalon products are subject to wear and tear; boats, marine fenders and dracone barges are subject to harsh treatment when in unsettled waters, whilst wet suits are placed in and out of sea water and left to dry in the sun. Most adhesives could not withstand such extreme conditions. Stormoprene (A3703) ensures a safe and secure bond in these conditions because it has a temperature resistance of -30°C - 120°C and is resistant to both sea water and chemicals.Directions:

1. Mix components A (adhesive) & B (curing agent) for approx. five minutes. Ideally, mix in the proportions supplied or by components A & B at a ratio of 100:6 by weight.

2. Apply an even coat of the mixed adhesive to both surfaces with a brush, roller coater or serrated trowel. Allow the adhesive to dry for 5-15 minutes or until it is dry to touch.

Please note: Applying two thin coats of adhesive is preferable to ensure maximum adhesion. Leave the first coat to dry for approximately 20-30 minutes before applying the final coat. Allow the final coat to dry for 5 to 15 minutes.

3. Join the surfaces together using as much pressure as possible. This is to prevent air entrapment. Components may be handled within minutes of being bonded.

-

Stormsure Latex Wrist Seal Repair Kit (Bottle Neck Shape)£19.00

This kit contains all the components that you need to replace the bottleneck shaped wrist seal on a drysuit. Full instructions are on the pack. Make a good quality water tight repair at a fraction of the cost of sending the suit away for repair.

Stormsure Bottleneck Shaped Wrist Seal

High Quality Latex made in the UK

Size: Medium

Top Cone: 44mm diameter

Bottom Cone: 89mm diameter

Height: 120mm

Stormoprene Adhesive

Stormoprene Hypalon Adhesive is a specially formulated 2-part poly-chloroprene based adhesive system for high-performance bonding of Hypalon and other natural and synthetic rubber surfaces that require high strength bonds for use in demanding applications.

Formulated for use in the manufacture and repair of RIBs, inflatable boats, liferafts, diving suits, wet suits and other marine and industrial applications that specify resistance to salt water, oil, fuels etc.

Directions:

1. Cut off the damaged seal, leaving the part of the suit where the factory seal is attached to the fabric. The new seal will be glued over the old factory seal edge.

2. Slide the new seal into the factory edge and put an elastic band or bungee around the suit to keep it in place. Slide some silicone/wax paper under the cut off edge to keep glue from sticking to the seal, or you can put wax on the seal.

3. Clean the edge of the suit and the new seal edge with solvent (the side with the stripes is the inside.) Gently sand paper it to roughen the surface. Do not let the seal stick out too far, as the small end of the seal should not be stretched over it. It might cause the new seal to slide out of position.

4. Slide the seal on over the factory rubber area. You can put elastic bands around to keep the new seal from sliding.

5. Roll back the new seal so that the 2cm edge that was over the old suit is now facing up. Apply a thin layer of Stormoprene Contact Adhesive to each side. Wait 5 minutes and apply a second layer of adhesive to each side. Use a spatula or knife to apply the glue. When the glue is touch dry, roll the new latex seal right into place over the rubber part of the old seal. It bonds instantly. Press firmly over the glue area to ensure full adhesion.

6. Take your time.

-

Stormsure Inflatable Tent Repair Kit£9.98

The Inflatable Tent Repair Kit is expertly designed for the repair of inflatable tents, an essential kit for campers and outdoor enthusiasts. It includes a 5g tube of Stormsure Flexible Repair Adhesive, two TUFF Tape repair patches, a TUFF Tape strip, disposable gloves, a spatula, and an alcohol wipe, providing all the necessary tools for fixing punctures, tears, and leaks in inflatable tents.

Kit Contents:

-

1x 5g Tube of Stormsure Flexible Repair Adhesive: A powerful adhesive that offers a waterproof, flexible bond, perfect for sealing and repairing punctures and tears in inflatable tents.

-

2x TUFF Tape Repair Patches (75mm diameter): Self-adhesive patches designed for quickly fixing larger damages, providing a strong, durable repair.

-

1x TUFF Tape Strip (15cm long x 7.5cm wide): A versatile repair strip for covering longer tears or reinforcing seams and edges on the tent.

-

1x Pair of Disposable Gloves: To keep hands clean and protected during the repair process.

-

1x Spatula: Useful for applying and spreading the adhesive smoothly and evenly.

-

1x Alcohol Wipe: For cleaning the repair area to ensure the best possible adhesion.

Key Features:

-

Specially Formulated for Inflatable Tents: The adhesive and repair materials are chosen for their effectiveness with inflatable tent fabrics.

-

Durable and Waterproof Repairs: Suitable for outdoor use, ensuring repairs can withstand various weather conditions and retain air pressure.

-

Easy and Convenient to Use: The kit enables quick DIY repairs, ideal for camping trips and outdoor activities.

-

Comprehensive Repair Solution: Offers both adhesive and patch options to cater to different types of tent damages.

-

Portable and Lightweight: Compact size makes it an essential addition to camping gear for emergency or routine maintenance.

Benefits:

- Cost-Effective: Extends the life of inflatable tents, avoiding the need for expensive replacements.

- Rapid Repair Capability: Perfect for on-the-spot repairs, reducing downtime during camping trips.

- Strong and Reliable Repairs: Ensures a long-lasting fix that can withstand the rigors of camping and outdoor use.

- Maintains Tent Integrity: Preserves the functionality and performance of the inflatable tent.

How to Use:

- Clean the damaged area with the alcohol wipe and let it dry.

- Apply the adhesive to smaller punctures or tears. For larger damages, use a TUFF Tape patch or the strip over the adhesive.

- Use the spatula for even adhesive application and wear disposable gloves for protection.

- Press the patch or strip firmly to create a secure bond.

- Allow the adhesive to cure completely for 24 - 48 hours before inflating and using the tent.

The Inflatable Tent Repair Kit is a must-have for anyone who uses inflatable tents, offering an efficient, effective, and reliable solution for maintaining and repairing these unique camping shelters. Whether you're dealing with a minor puncture or a larger tear, this kit ensures that your inflatable tent remains a reliable and comfortable shelter on all your outdoor adventures.

-

-

TUFF Tape Self-Adhesive Waterproof Repair Tape 10m x 75mm£34.96

Stormsure ’TUFF Tape’ is a very strong, clear, self-adhesive, waterproof tape that is sold as individual pre-cut patches and strips of various shapes and sizes. TUFF Tape is made of a thin, but very tough, polyurethane film with a pressure sensitive adhesive and backing paper on the rear side. It has characteristics unlike many other tapes. It is waterproof and air tight. It is highly resistant to abrasion and very difficult to tear or puncture. It stretches and is elastic and it can withstand both heat and extreme cold without losing all its useful characteristics. TUFF Tape is very strong and can bind together items just by stretching the tape around the item and using the elasticity to pull the pieces tightly into place. When TUFF tape is applied to clothing it will go through regular washing machine cycles unaffected.

USES: Use TUFF Tape to quickly repair rips in waterproof clothing, ripped netting and fabrics, inflatable mattresses, canoes and RIBs, tents and awnings, sails and kites, waders, cracked buckets and other plastic containers, PVC curtain sides on trucks and warehouses.

DIRECTIONS: Ensure that the surface is clean and dry before using. Cut a suitable sized piece of TUFF Tape for your repair using good quality scissors or a sharp scalpel blade. Peel off the backing paper. Carefully position and then apply the TUFF Tape directly on top of the damage. Start at one edge and press the tape down gradually to avoid the entrapment of air bubbles. Once the TUFF Tape is in place rub it firmly with a smooth and hard object (such as the back of a spoon) to ensure the maximum adhesion to the substrate.

-

Stormsure Flexible Repair Adhesive 10x5g£20.95

It's all about Stormsure Flexible Repair Adhesive

How to Repair using Polyurethane Adhesive

Stormsure Flexible Repair Adhesive is a polyurethane based adhesive and can be used in situations that demand extremely high durability, strength and flexibility. The degree of elasticity offered allows for use for both static as well as for more flexible bonding and sealing purposes. These adhesive types are formulated from polymers and solvents.

- Stormsure can be used as either an adhesive to join two surfaces together, or as a surface sealant when spread over just one surface.

- Bonds to virtually all surfaces. It allows bonding wood, concrete, stone, metals, laminate, plastics, glass, PU, and most flexible natural and man made fabrics on themselves or in combination. It can also be used to glue models, flexible fabrics, inflatable items, waterproof items, brickwork, joinery and a huge range of other things too.

- Stormsure is a liquid clear polyurethane-based (PU) adhesive that has been specifically developed to provide strong and reliable bonding to a wide range of materials

- Stormsure is a one-part polyurethane adhesive that reacts with moisture to polymerize and cure which provides very strong and waterproof bonding. It is suitable for indoor and outdoor use.

- The glue is transparent so it won't normally discolour the objects you need to join.

- Always check for compatibility on fabrics in an inconsipcuous area before making a major repair. It is used for repairs and construction where a very high connection strength is required. It can be used indoors and outdoors and will last for a long time under water too.

- Complete curing time: 10-12 hours. Resistent to temperatures from -30°C to +80°C.

- How to use: Surfaces to be bonded must be clean and free of dirt (dust, grease, etc.). Apply glue to one of the surfaces to be bonded. Assemble immediately and press firmly together and immobilize for at least 24 hours.

- TIPS: Store partly-used tubes in a deep freezer. Warm up to room temperature before re-use. Cured clear adhesive may change to a pale yellow colour when exposed to bright light.

The Science

In the case of Stormsure adhesive – the liquid glue will start to cure when it is exposed to even the smallest amount of water vapour in the air. This initiates a chemical chain reaction which will continue until all the glue has cured. The glue should be used at room temperature (15°C - 25°C for best results). Do not use below 5°C. If the glue is too cold the it may appear white and waxy. - Just warm it up until it is a transparent liquid again and it will work fine.

This adhesive is a single component moisture curing product. It has 70% solids content and will only shrink slightly as it cures but this helps to create a very strong and tight bond on most surfaces. It can be used to fill gaps and holes.

What is it used for?

Stormsure adhesive is incredibly versatile, making it a good choice for those needing an all-purpose adhesive that is flexible and durable. Stormsure can be used to bond leather, tile, rubber, PVC, wood, concrete, stone, metals, laminate, most plastics glass and PU on themselves or in combination. It can also be used to glue models, joinery, door sills, stairs, skirting boards, window sills.

Other Characteristics

It also offers complete water resistance and allows sanding and painting when it has dried completely. Polyurethane glue can also fill and even out inconsistencies in the surface you use it on. Characteristics like these, and numerous others, make this type of adhesive an essential tool that is well suited for a wide range of bonding applications.

- Stormsure Flexible Repair Adhesive is a liquid clear polyurethane-based (PU) adhesive that has been specifically developed to provide strong and reliable bonding to a wide range of materials.

- Stormsure Flexible Repair Adhesive is a one-part polyurethane adhesive that reacts with moisture to polymerize and cure which provides very strong, flexible and waterproof bonding.

- The glue is transparent. It is also available in White, Khaki and Black. It is used for repairs and constructions where a very high connection strength is required and can be used indoors, outdoors and gor repairs that will be under water..

- This glue increases its volume when curing allowing it to fill irregularities. It is resistant to humidity (Class D4), shock and vibrations and temperature variations.

How To Use Stormsure

Surfaces to be bonded must be clean and free of dirt (dust, mud, grease, etc.). You can use an alcohol wipe to clean the surfaces, if not, then just soap and water will do. Be sure the surfaces are dry before application. Apply the glue to one of the surfaces to be bonded. To ensure the best result, at least one of the surfaces must be porous or permeable. Thus, it is recommended to sand/roughen smooth surfaces. Assemble immediately. Press strongly and immobilize for at least 10-12 hours.

Conclusion

Despite the marginally higher cost of polyurethane adhesives, they do offer plenty of worthwhile benefits. They are well suited for use with a variety of different materials, and their strong adhesion allows single-sided application. Polyurethane adhesives are easy to work with. Polyurethane adhesives are also highly resistant to the elements and can endure heavy contact and impact.

-

Stormsure Flexible Repair Adhesive 3x5g Black£7.96

It's all about Stormsure Flexible Repair Adhesive

How to Repair using Polyurethane Adhesive

Stormsure Flexible Repair Adhesive is a polyurethane based adhesive and can be used in situations that demand extremely high durability, strength and flexibility. The degree of elasticity offered allows for use for both static as well as for more flexible bonding and sealing purposes. These adhesive types are formulated from polymers and solvents.

- Stormsure can be used as either an adhesive to join two surfaces together, or as a surface sealant when spread over just one surface.

- Bonds to virtually all surfaces. It allows bonding wood, concrete, stone, metals, laminate, plastics, glass, PU, and most flexible natural and man made fabrics on themselves or in combination. It can also be used to glue models, flexible fabrics, inflatable items, waterproof items, brickwork, joinery and a huge range of other things too.

- Stormsure is a liquid polyurethane-based (PU) adhesive that has been specifically developed to provide strong and reliable bonding to a wide range of materials

- Stormsure is a one-part polyurethane adhesive that reacts with moisture to polymerize and cure which provides very strong and waterproof bonding. It is suitable for indoor and outdoor use.

- The glue is transparent so it won't normally discolour the objects you need to join.

- Always check for compatibility on fabrics in an inconsipcuous area before making a major repair. It is used for repairs and construction where a very high connection strength is required. It can be used indoors and outdoors and will last for a long time under water too.

- Complete curing time: 24 hours. Resistent to temperatures from -30°C to +80°C.

- How to use: Surfaces to be bonded must be clean and free of dirt (dust, grease, etc.). Apply glue to one of the surfaces to be bonded. Assemble immediately. Press strongly and immobilize for at least 10-12 hours.

- TIPS: Store partly-used tubes in a deep freezer. Warm up to room temperature before re-use.

The Science

In the case of Stormsure adhesive – the liquid glue will start to cure when it is exposed to even the smallest amount of water vapour in the air. This initiates a chemical chain reaction which will continue until all the glue has cured. The glue should be used at room temperature (15°C - 25°C for best results). Do not use below 5°C. If the glue is too cold the it may appear white and waxy. - Just warm it up until it is a liquid again and it will work fine.

This adhesive is a single component moisture curing product. It has 70% solids content and will only shrink slightly as it cures but this helps to create a very strong and tight bond on most surfaces. It can be used to fill gaps and holes.

What is it used for?

Stormsure adhesive is incredibly versatile, making it a good choice for those needing an all-purpose adhesive that is flexible and durable. Stormsure can be used to bond leather, tile, rubber, PVC, wood, concrete, stone, metals, laminate, most plastics glass and PU on themselves or in combination. It can also be used to glue models, joinery, door sills, stairs, skirting boards, window sills.

Other Characteristics

It also offers complete water resistance and allows sanding and painting when it has dried completely. Polyurethane glue can also fill and even out inconsistencies in the surface you use it on. Characteristics like these, and numerous others, make this type of adhesive an essential tool that is well suited for a wide range of bonding applications.

- Stormsure Flexible Repair Adhesive is a liquid clear polyurethane-based (PU) adhesive that has been specifically developed to provide strong and reliable bonding to a wide range of materials.

- Stormsure Flexible Repair Adhesive is a one-part polyurethane adhesive that reacts with moisture to polymerize and cure which provides very strong, flexible and waterproof bonding.

- The glue is black. It is also available in White, Khaki and Clear. It is used for repairs and constructions where a very high connection strength is required and can be used indoors, outdoors and gor repairs that will be under water..

- This glue increases its volume when curing allowing it to fill irregularities. It is resistant to humidity (Class D4), shock and vibrations and temperature variations.

How To Use Stormsure

Surfaces to be bonded must be clean and free of dirt (dust, mud, grease, etc.). You can use an alcohol wipe to clean the surfaces, if not, then just soap and water will do. Be sure the surfaces are dry before application. Apply the glue to one of the surfaces to be bonded. To ensure the best result, at least one of the surfaces must be porous or permeable. Thus, it is recommended to sand/roughen smooth surfaces. Assemble immediately. Press strongly and immobilize for at least 10-12 hours.

Conclusion

Despite the marginally higher cost of polyurethane adhesives, they do offer plenty of worthwhile benefits. They are well suited for use with a variety of different materials, and their strong adhesion allows single-sided application. Polyurethane adhesives are easy to work with. Polyurethane adhesives are also highly resistant to the elements and can endure heavy contact and impact.

-

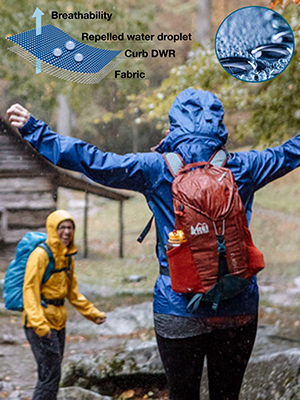

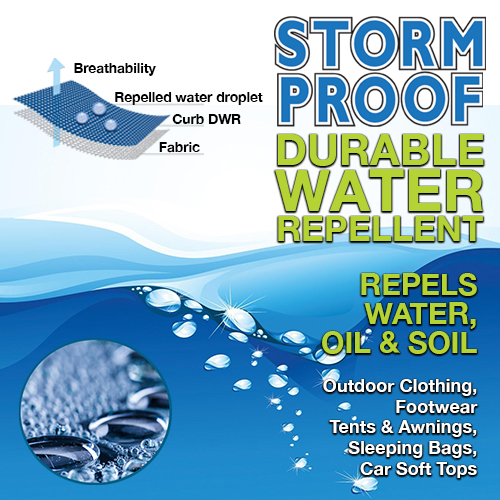

Stormproof Durable Water Repellent 25L Concentrate£699.86

View the Stormproof size guide HERE

For wet weather garments and equipment

Stormsure's Stormproof is a spray-on durable water repellent that you should use on outdoor gear such as foul weather clothing, raincoats, woollen coats, hats, breathable jackets, fleeces, tweeds, synthetics, tents and footwear.

- It effectively repels water, oil and soil and works perfectly on nylon, cotton, polyester, wool, leather and more. Water just rolls off the surface without wetting it.

- To use, simply spray evenly onto your garment and allow to fully dry in a warm place.

- Stormproof is non-toxic and does not have a nauseating chemical smell, meaning it can be used in any environment and not necessarily outdoors.

- Easy spray-on application method for all types of fabrics. Water based, fluorocarbon-free & environmentally responsible

Available in 250ml, 500ml, 1L, 5L and 25L

Unlike some other waterproofing sprays, Stormproof is non-toxic and does not have a nauseating chemical smell, meaning it can be used in any environment and not necessarily outdoors.

- Works great with climatic membranes like GORE-TEX

- Adds or renews water repellency and revives breathability

- Prolongs the life of gear and optimises outdoor performance

-

Stormsure Flexible Repair Adhesive 15g Clear£7.20

It's all about Stormsure Flexible Repair Adhesive

The Stormsure Flexible Repair Adhesive Clear (15g) is a versatile, high-strength adhesive designed for a wide array of repair needs. This clear adhesive is perfect for a multitude of applications, offering a flexible, waterproof, and durable bond. It's ideal for repairing items like outdoor gear, footwear, inflatable items, tents, and much more, ensuring a reliable and long-lasting fix.

Key Features:

- Strong and Flexible Bond: Provides a robust bond that remains flexible once cured, ideal for materials that need to retain elasticity.

- Clear Formula: The adhesive dries clear, making it suitable for repairs where appearance is important, leaving a clean and unobtrusive finish.

- Waterproof and Durable: Once cured, the adhesive creates a waterproof seal, making it perfect for outdoor and water-related repairs.

- Multipurpose Use: Ideal for repairing a wide range of materials, including rubber, leather, PVC, neoprene, canvas, and various fabrics.

- Easy Application: The tube allows for precise application, making it simple to apply the right amount of adhesive exactly where it's needed.

Benefits:

- Versatile Repair Solution: Suitable for everything from patching a tent to fixing a shoe sole or mending an inflatable pool toy.

- Cost-Effective: Saves money by enabling easy repairs instead of needing to replace damaged items.

- Long-Lasting Repairs: Offers a durable solution that withstands wear and tear, as well as exposure to the elements.

- User-Friendly: Easy to use for both quick fixes and more complex repairs.

How to Use:

- Ensure the surface to be repaired is clean and dry.

- Apply the adhesive directly to the damaged area.

- If necessary, press the two surfaces together and remove any excess adhesive.

- Allow to cure for 12-24 hours (depending on conditions) for optimal strength.

The Stormsure Flexible Repair Adhesive Clear (15g) is an essential tool for any repair kit, whether at home, in the workshop, or on the go. It's a go-to solution for a diverse range of repair tasks, ensuring that your gear and items remain functional and well-maintained, saving time and money in the long run.

-

Stormsure Flexible Repair Adhesive 15g (with Precision Nozzle)£6.76

Stormsure Flexible Repair Adhesive is a very strong general purpose adhesive and it can also be used as a surface sealant. It exhibits special characteristics unlike many adhesives as it is highly flexible and stretchy after it has cured but it remains very strong. It fills gaps well, it is suitable for use indoors and outdoors and in marine environments. The adhesive can be painted on top of a surface to make it waterproof, airtight or abrasion resistant. Stormsure adhesive can often be used to cover holes without a patch. A thick film of adhesive will make a good repair. If the glue will drip through the hole just place some sticky tape behind the hole before applying the glue. It can be removed once the glue has cured.

Stormsure Flexible Repair Adhesive bonds to virtually all surfaces including neoprene, rubber, leather, PVC, polyurethane, breathable and coated fabrics, wood, metal and more. It is ideal for repairing cracks in rubber wellington boots, hiking boots, loose soles, leaks in waders, rips in wetsuits, damaged horse rugs, holes in tents and canopies, leaks and splits inflatable items and many other items too. It can also be used for repairs to woodwork and furniture, roof tiles and concrete.

A tube of Stormsure Flexible Repair Adhesive is an essential part of a repair kit for hikers, DIY, fishermen, equestrians, hunters, divers, campers, surfers, sailors, engineers etc!

Comes with disposable gloves.DIRECTIONS: Use the adhesive at room temperature. Clean the damaged area to remove dirt and grease (sandpaper the surface for best adhesion). Apply a generous amount of Stormsure Flexible Repair Adhesive to the damaged area, with at least a 5mm extra around the damaged area. Leave horizontal and allow to cure for 10-12 hours.

TIPS: Store partly-used tubes in a deep freezer. Warm up to room temperature before use again.

-

Stormproof Durable Water Repellent 5L Refill£49.96

View the Stormproof size guide HERE

For wet weather garments and equipment

Stormsure's Stormproof is a spray-on durable water repellent that you should use on outdoor gear such as foul weather clothing, raincoats, woollen coats, hats, breathable jackets, fleeces, tweeds, synthetics, tents and footwear.

- It effectively repels water, oil and soil and works perfectly on nylon, cotton, polyester, wool, leather and more. Water just rolls off the surface without wetting it.

- To use, simply spray evenly onto your garment and allow to fully dry in a warm place.

- Stormproof is non-toxic and does not have a nauseating chemical smell, meaning it can be used in any environment and not necessarily outdoors.

- Easy spray-on application method for all types of fabrics. Water based, fluorocarbon-free & environmentally responsible

Available in 250ml, 500ml, 1L, 5L and 25L

Unlike some other waterproofing sprays, Stormproof is non-toxic and does not have a nauseating chemical smell, meaning it can be used in any environment and not necessarily outdoors.

- Works great with climatic membranes like GORE-TEX

- Adds or renews water repellency and revives breathability

- Prolongs the life of gear and optimises outdoor performance