Silicone

Subscribe to RSS Feed

It's waterproof and flexible, making it ideal for sealing seams exposed to rain and other elements.

• Non-Staining

• Highly water repellent

• Highly resistant to weathering and ageing

• Electrically insulating Environmentally friendly, both in its production and in its application

• Resistant to many acids and other chemicals

Read more here: "What is Silicone? and Silicone Adhesive and Sealant?"

-

Price £0.00 - £99.99 Remove This Item

- Clear All

-

Non-Staining Clear Silicone Adhesive Sealant 80ml£9.95

What is Silicone?

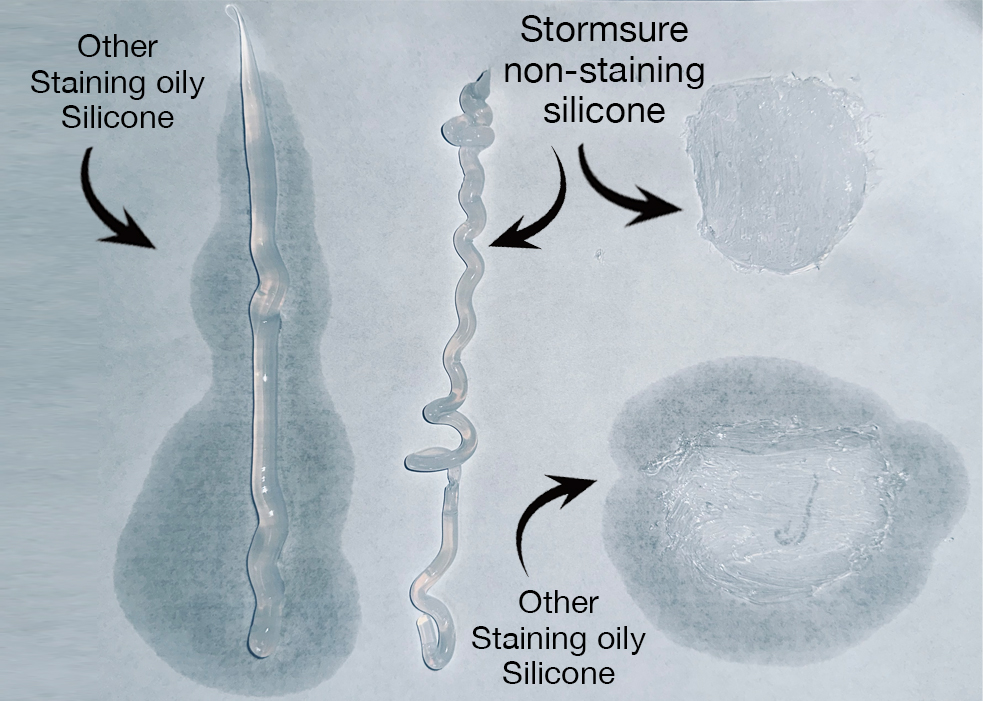

• Stormsure Silicone is a Non-Staining No Oily Residue Silicone Adhesive and Sealant (Not all silicone adhesives are non-staining).

• Highly water repellent

• Highly resistant to weathering and ageing

• Electrically insulating Environmentally friendly, both in its production and in its application

• Resistant to many acids and other chemicals

Using silicone as a seam sealer: This type of sealer is ideal for outdoor gear and clothing made from synthetic materials. It's waterproof and flexible, making it ideal for sealing seams exposed to rain and other elements.

It is also ideal for sealing brickwork, tiles, slabs and concrete.

Advantages and Disadvantages of Silicone-Based Adhesives

A silicone rubber adhesive offers the user many different advantages:

PROS

• Temperature-resistant in a range from -85° to 572° Fahrenheit (-65° to 300° Celsius).

• Suitable for outdoor and indoor use

• Waterproof

• High UV and weathering resistance

• Highly elastic, making it suitable for bonding materials with different coefficients of thermal expansion, as well as for bonding vibrating parts Electrical non-conductor

CONS

Cannot withstand very high vibrations and strong movement loads in the long term due to its elasticity

One-component silicone adhesives generally not suitable for high-strength bonding that must withstand large loads on a permanent basis – over time, the silicone may wear and come loose

Cannot be painted over Produce an unpleasant odour of vinegar during curing phase

What is it used for?

The areas of application for silicone adhesives are diverse. For example, materials can be reliably bonded together, especially outdoors, where the adhesive seam must be weather-resistant and waterproof. Bonding and attaching tiles is also no problem with a silicone rubber adhesive. The following materials are reliably bonded with silicone-based glues:

• Outdoor gear and clothing made from synthetic materials

• Sealing seams exposed to rain and other elements

• Wood

• Glass

• Various plastics

• Metal

• Ceramics

• Enamel

• Paper and cardboard

• Brickwork, tiles, slabs, concrete

• Bathroom and kitchen sealant

Many users place particular emphasis on the ease of processing and flexibility of silicone, which is ideal for bonding substrates that are permanently exposed to vibrations or temperature fluctuations, such as:

• Parts on automobiles

• Fastening of illuminant parts

• Computer components

• Kitchen parts, for example on ovens or other electrical appliances

Preparation

Before you can bond the silicone, you must clean the substrates thoroughly. These must be free of any dirt, dust, oil, and grease. Any old grout must also be removed before you can bond new tiles with silicone, for example. The tiles to be laid or the other substrates can be cleaned with by rinsing it with water, but also with isopropanol or acetone.

Allow the surfaces to dry completely before starting the silicone bonding process. If the substrates show very uneven areas, these must still be filled or the surrounding raised areas must be ground down. Silicone is not suitable for bridging large gaps during the bonding process.

The Bonding Process

Before you apply the silicone adhesive to the actual substrates, it is recommended that you practice on a piece of cardboard. If the handling works well, you can apply the silicone to the substrates. Silicone can now be applied to one side of the entire surface to be bonded. If it is a large area, set the silicone more generously, but not too thickly. You can spread it out using a spatula.

Curing time should be 4-6 hours. But leave for 24 hours for complete cure.

The Finish

Stormsure is a NON-Staining Silicone Adhesive and Sealant.

Click here to read more on how to use Stormsure Silicone as a sealant